Self-Locking Torque Inspection Specification for Chemical Adhesives

Basic Specifications

◎ External and internal diameters of Metric screw threads must meet the requirement of ISO 965-2:1998.◎ External and internal diameter of British Standard screw threads must meet the requirement of ASME B1.1:2003.

◎ External threads of counterparts must meet the tolerance of 6g ring gauge. Internal threads of counterparts must meet the tolerance of 6H bolt gauge.

◎ For internal threaded counterpart, chamfer processing is necessary and it should not have any sharp burr.

◎ The coating length should be at least 0.8d, and the coating design should be based on the actual locking position on the counterpart.

◎ The design of self-locking torque is mainly based on DIN 267-27 (with preload) specification. Please consult us in advance for any special requirement.

◎ During the locking process, fasteners and its counterparts cannot be contaminated by any oil and solvent.

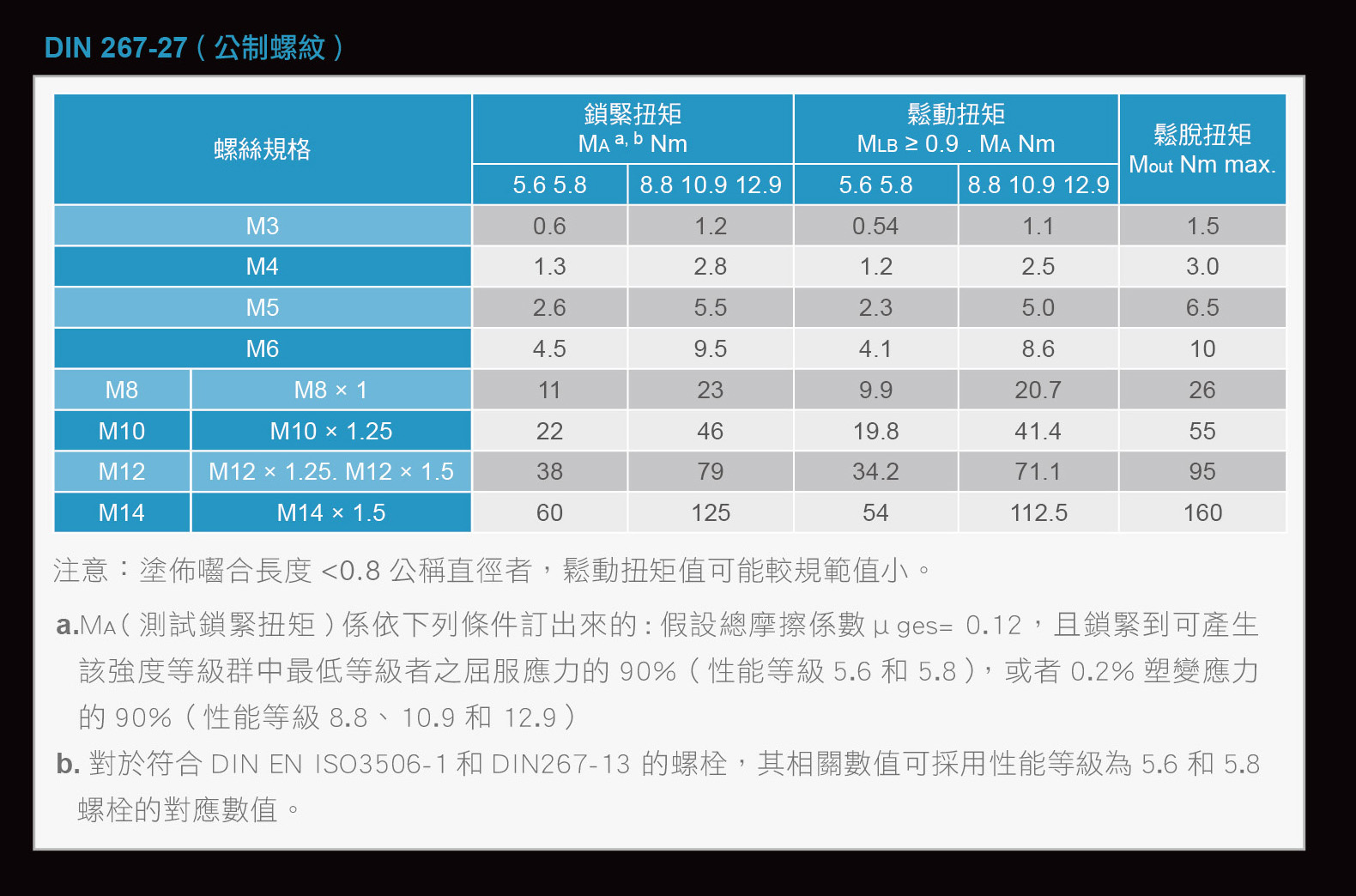

Chemical Adhesive Inspection Specification: DIN 267-27

DIN stands for Deutsches Institut für Normung. It is a very important standardization organization based in Germany. Many of its standards are adopted by EN and ISO, which have been widely used internationally.

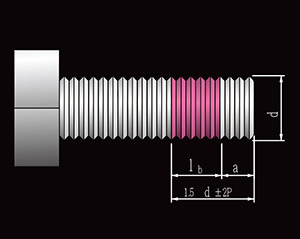

Specification for Chemical Adhesive coating (according to DIN 267-27) :

lb: Length of coated zone

d: Nominal thread diameter

a: Two or three turns of thread left uncoated

P: Pitch

*For non-standard coating design, please consult our sales engineering team in advance.

Test torques and test torque ratios at ambient temperature and at temperatures of 100°C and 150°C (preloaded bolt)

Ratio (preloaded bolt)

(Reference for automobile and conventional industry application. May not be applicable to special use and applications)